Connector testing is the most important phase in the verification of electrical connector safety. The verification of responsible design and manufacturing is done in testing laboratories with valid testing and certification standards.

Testing and certification

In the testing phase, the connector is loaded very intensely, over the limit values assigned to the product. The connector also has to withstand temperatures higher than in a normal usage situation. Compression connectors are also tested for the pull-out, where the conductor must not detach from the connector. The testing phase preceding the certification is an investment for the manufacturer, but a very necessary one.

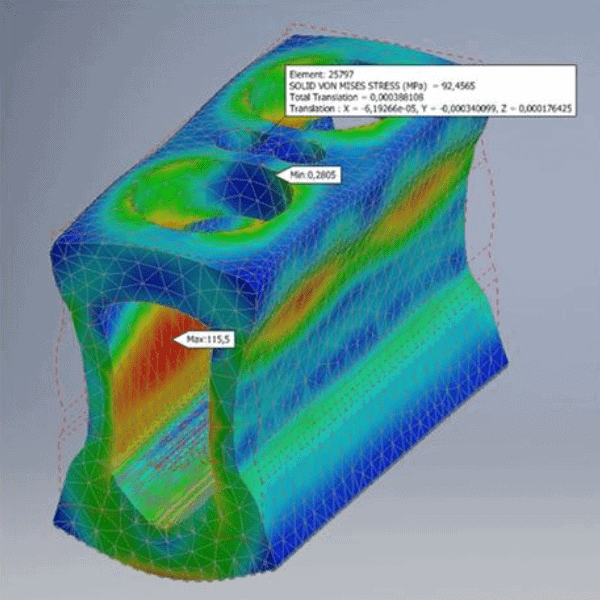

Prior to testing, here at Ouneva we simulate different forces that the connectors have to withstand. For example, with the OTL connectors, we simulate tests to the connector body of possible tensions and stretching caused by the connector screws. The simulation phase makes our product development more streamlined, and we also get to verify the functionality of the connector even before testing. This means no surprises in the testing laboratory.

The testing of connectors manufactured by Ouneva is done in accredited laboratories according to the testing standards. The tests are divided into multiple parts, including mechanical and electrical tests. In the electrical tests, multiple parameters are measured in the product, from where the electrical safety and quality of the product can be verified.

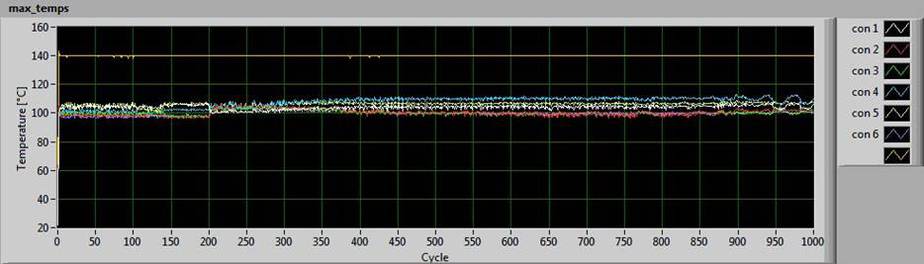

In this case, the connectors had a slight reaction to the short-circuits in cycle 200/1000, but the variation is so small that it is insignificant. The connectors passed the test.

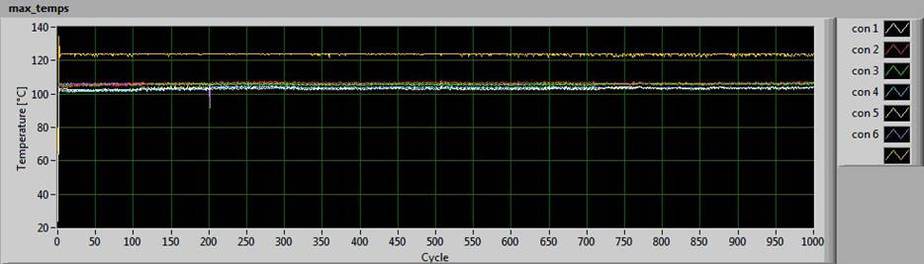

This case shows no variation in the temperatures after the short-circuits, the connectors passed the test.

Only high-quality and safe connectors pass the tests defined by the standard. After an approved testing phase, the testing laboratory drafts a test report and a certificate, and their validity and equivalence are monitored on behalf of the laboratory.

For example, the OTL connector family is tested according to the following standards:

– EN 61238-1:2003 Class A

– EN 60947-7-1:2009

– EN 60947-7-2:2009

– UL 1059, CAN/CSA C22.2 No. 158-10, Terminal blocks.

OTL connectors are certified for use with copper and aluminium conductors, from which the use of aluminium especially has grown a lot. This makes the OTL connectors applicable for a broad variety of use keeping the safety point of view in mind.

What’s the difference between a Class A and a Class B connector?

Connectors can be classified into two different classes, A and B. The difference of a Class A connector to Class B is that Class A connectors are also short-circuit tested. This means that Class A connectors have a much wider variety for usage comparing to a Class B connector. Class A connectors are also more cost-efficient, considering that due to the short-circuit test they do not require separate quick circuit breakers. These circuit breakers are often expensive in acquiring and installation costs.

What other safety aspects should you consider when choosing a connector?

Material choices should be taken into account already in the design phase. Correct material choices influence the price, quality and recyclability of the end product. They also make a great impact on product safety, and especially fire safety, which is a significant part.

The OTL connector family is manufactured using plastic materials, whose fire rating fulfills the requirements of the UL 94 test standard V-0. V-0 classified materials do not boost fire and are self-extinguishing. The classified materials are tested by UL and a material certificate, a so-called “yellow card”, is available for viewing. The fire rating has been accomplished without halogens, which means that the materials in the OTL connector family are completely halogen-free.

When choosing an electrical connector, you should pay attention to the certification of the product. We highly recommend you to choose a Class A connector to ensure the safety of the connector. The OTL connector family is full of high-quality, tested and certified products that give you the best installation and user properties. If you’re interested in certified manufacturers, here is a link to directory of manufacturers certified by SGS, so you can be sure about the quality and safety of the product you choose; https://www.sgs.fi/fi-fi/certified-clients-and-products/certified-client-directory